Vac Forming Process

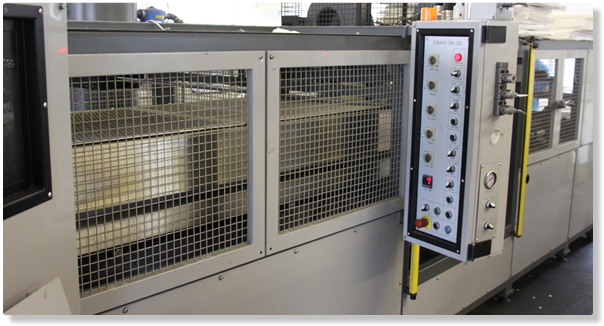

Thermoforming or Vacum Forming is a process which uses heat and pressure and/or vacuum to form parts from an extruded (flat) sheet of plastic. Our automated process pulls the plastic from large rolls, heats it to its softening temperature, and then formed into the desired shape using an aluminum mold. It is then cut into individual containers, inspected, boxed, and shipped.

We specialize in thin gage parts formed from sheet thickness of 4mil to 60mil (.004” to .06” or .1mm to 1.52mm).

In contrast to Injection Molding, Thermoforming Tooling is very affordable.

Copyright © 2025 Mipack Limited | Website Design Manchester by FLUID DIGITAL